Cheap epoxy floors can seem like a real bargain, but they often have hidden headaches.

In this article, we’ll reveal the not-so-obvious dangers of low-quality epoxy flooring and show you how to avoid them.

Stick with us to learn how to protect your hard-earned money and ensure you have top-install epoxy flooring that’s safe and built to last.

Key Takeaways

- Cheap epoxy floors often fail due to poor adhesion, peeling, moisture issues, and air bubbles caused by improper installation and low-quality materials.

- Low-grade epoxy can release harmful fumes that may cause skin irritation, breathing problems, and long-term health risks like asthma or allergies.

- High-quality epoxy flooring offers durability, chemical resistance, and easy maintenance, and it is available in a wide range of colors and finishes.

- Polyurea coatings, which last about 15 years and cure faster, are alternatives to epoxy. They cost $7 to $12 per square foot.

- Other durable options are polished concrete and epoxy terrazzo, which resist stains and scratches while allowing for unique designs.

Understanding Epoxy Flooring

Epoxy flooring offers a durable and attractive solution for many spaces. We’ll explore its key features and why quality matters in this popular flooring choice.

Definition and Expected Uses of Epoxy Resin

Epoxy flooring is a tough plastic made from epoxy resins and curing agents. It’s used in garages, sports centers, factories, stores, and homes. People like it because it’s strong and looks good.

Epoxy floors are easy to clean and can be made in different colors and styles.

Our clients love installing epoxy flooring for its many benefits. It guards concrete from stains and damage. This flooring is as strong as vinyl but as pretty as hardwood. It stands up to chemicals and heavy use.

Many choose it for its low upkeep costs and long life. We often install it where floors need to be both tough and attractive.

Benefits of High-Quality Epoxy Flooring

High-quality epoxy flooring offers many perks for California property owners. It bonds well to existing surfaces, creating a tough layer that lasts. This strong bond means the epoxy floor coating can handle heavy foot traffic and resist impacts.

Epoxy floors also withstand harsh environmental conditions, chemicals, and extreme temperatures. They’re easy to clean and maintain, saving time and money in the long run.

A high-quality epoxy floor is an investment in durability and aesthetics.

Our clients at Extreme Industrial Coatings love the wide range of colors and finishes available. Epoxy floors can be customized to match any style or brand. Safety is another big plus. We can add slip-resistant options to reduce accidents.

These benefits make epoxy an intelligent choice for many spaces. Now, let’s look at the risks of choosing cheap epoxy floors.

Risks Associated with Cheap Epoxy Floors

Cheap epoxy floors can lead to severe problems. Poor quality materials and rushed installation often result in peeling, bubbling, and uneven surfaces.

Poor Adhesion and Peeling

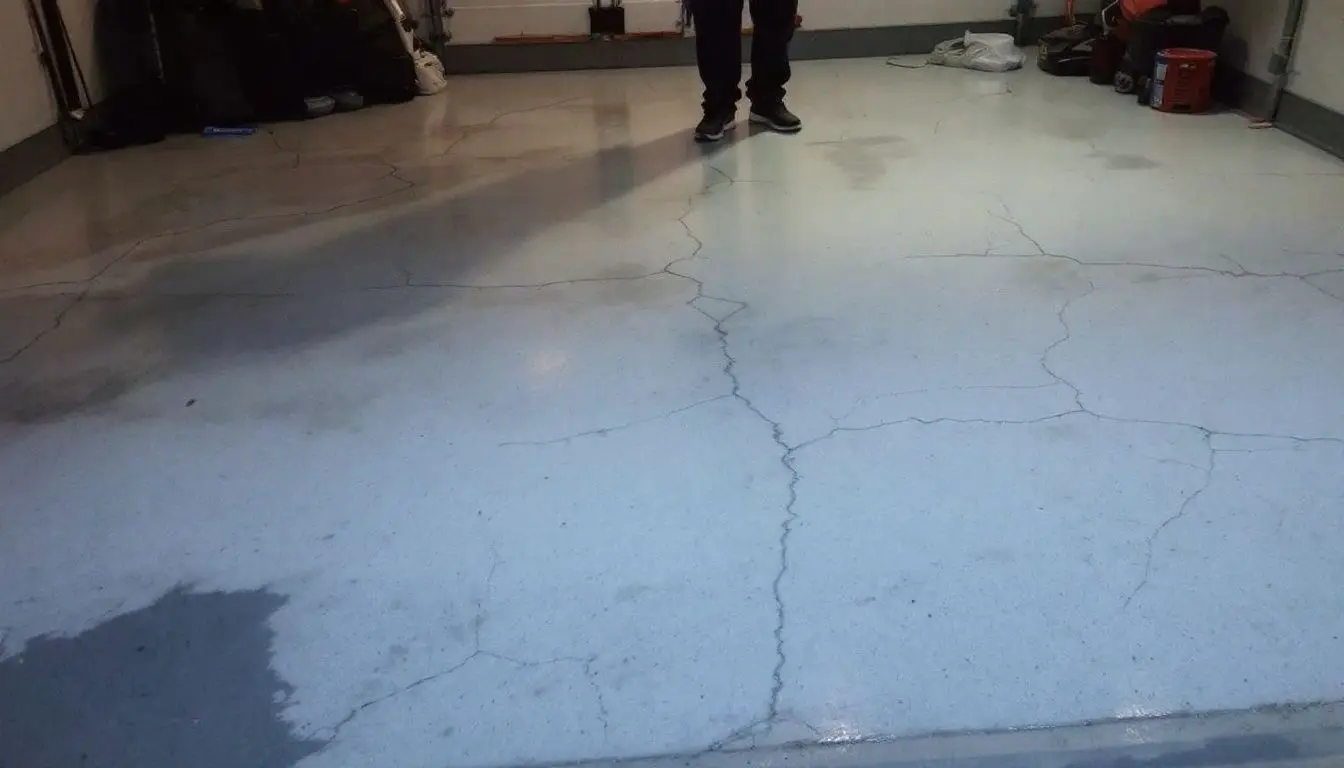

At Extreme Industrial Coatings, we often see cheap epoxy floors fail due to poor adhesion and peeling. These issues stem from several factors, including improper surface prep. Without the proper groundwork, epoxy won’t bond well to concrete.

The incorrect mixing of resin and hardener also leads to problems. The wrong ratio can cause the epoxy to peel away from the floor. Excess moisture is another enemy of good adhesion. It can seep under the floor coating and force it to lift.

Contaminated surfaces spell disaster for epoxy floors. Even tiny amounts of dirt or oil can prevent proper epoxy bonding. Skipping primer is another common mistake that leads to peeling.

We’ve found that many DIY installers and untrained pros make these errors. They often rush the job or cut corners to save money. But these shortcuts always cost more in the long run.

Peeling floors require frequent repairs and a new coat or complete redo.

Moisture and Air Bubble Issues

Moving from poor adhesion issues, we now face another major problem with cheap epoxy floors: moisture and air bubbles. Moisture is a big enemy of epoxy flooring. Most calcium chloride tests show levels above the safe 3 lbs limit.

This excess moisture can cause the epoxy to fail to dry out completely. Air bubbles are also a common issue. They form when epoxy is mixed too fast, trapping air in the mixture.

Proper preparation is the key to avoiding moisture and air bubble problems in epoxy flooring.

We must take steps to prevent these issues. Moisture tests and enough drying time are crucial before applying epoxy. Careful mixing is vital for air bubbles. If we use auto-scrubbing or wet grinding, we must let the floor dry fully before coating it.

These steps help create a smooth, long-lasting epoxy floor that withstands heavy foot traffic.

Inconsistent Coloring and Finish of Epoxy Coating

Beyond moisture issues, cheap epoxy floors often suffer from color problems. We’ve seen many cases where low-quality materials lead to uneven surface coloring. This inconsistency can ruin the seamless finish of your concrete floor, leaving you with a patchy, unprofessional finish.

Sunlight poses another threat to budget epoxy coatings. Over time, UV rays can cause yellowing or fading, especially in areas exposed to direct light. This effect is more pronounced with lower-grade products, which lack the UV resistance of premium options.

The result? A once-glossy floor that quickly loses its luster and appeal. We always stress the importance of using high-quality epoxy to ensure a long-lasting, attractive, glossy finish for your concrete flooring.

Health Concerns Linked to Low-Quality Epoxy

Low-quality epoxy can release harmful fumes during and after installation. These fumes may cause skin irritation, breathing problems, and other health issues.

Skin and Respiratory Irritation

At Extreme Industrial Coatings, we’ve seen many skin and breathing problems from cheap epoxy floors. These issues can start right away or build up over time. Epoxy fumes can hurt your eyes and throat.

They can also cause redness and swelling if they touch your skin.

Long-term use of low-grade epoxy might lead to worse health issues. People who work with it often may get asthma or skin allergies. Some even feel sick to their stomach or confused.

That’s why it’s crucial to choose high-quality epoxy and use it correctly.

Potential Long-Term Health Risks

Long-term exposure to cheap epoxy floors can pose serious health risks. Our research shows that low-quality epoxy resins often emit harmful fumes during and after curing. These fumes may cause respiratory issues, nausea, and headaches over time.

Imported epoxy products might not meet U.S. safety standards, putting users at greater risk.

Skin contact with uncured epoxy can lead to ongoing irritation and allergic reactions. People with existing sensitivities may face worsened symptoms from constant exposure. To avoid these dangers, it is crucial to choose high-quality epoxy or explore safer flooring options.

Let’s now look at some alternatives to epoxy flooring that can offer durability without health concerns.

Alternatives to Epoxy Flooring

Polyurea coatings offer a robust and flexible floor protection option. Other durable material choices include polished concrete, tile, and epoxy-alternative resins.

Polyurea Coatings

Extreme Industrial Coatings offers polyurea coatings as a top choice for concrete floors. These coatings resist UV rays, which stops them from yellowing over time. They also stand up better to heat than epoxy. Our polyurea floors last about 15 years, giving you great value.

You can walk on them in 6 hours and park cars in 24 hours. We back our polyurea floors with a 15-year warranty so that you can trust their quality.

Other Durable Flooring Options

While polyurea coatings offer great benefits, other durable flooring options exist for those seeking alternatives. Polished concrete stands out as a tough, low-maintenance choice. It resists stains, scratches, and moisture, making it ideal for high-traffic areas.

Epoxy terrazzo is another long-lasting option that combines durability with aesthetic appeal. Its customizable design allows for unique patterns and colors, perfect for those wanting a stylish yet robust floor.

These options provide excellent wear resistance and withstand heavy use, making them suitable for various California settings.

Conclusion

Cheap epoxy floors pose real risks. We urge caution when choosing floor coatings. Quality materials and proper installation matter greatly. High-grade epoxy floors offer long-lasting surface beauty and protection.

Your safety and satisfaction depend on making informed choices about flooring. Extreme Industrial Coatings is here to help.

FAQs

Contact Extreme Industrial Coatings today for 20+ commercial construction services we offer across California.

Leave A Comment